+86 15993886110

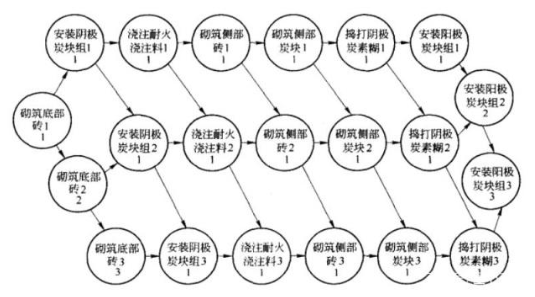

Aluminum electrolysis cell is the main thermal equipment in aluminium electrolysis production. There are many electrolytic cells in the aluminium electrolysis workshop. The construction of furnace construction is often carried out in parallel or cross with other professional projects. In order to gain time to speed up the progress of the project and to centralize and timely supply of various materials and energy, several electrolyzers are usually constructed at the same time. Each electrolyzer has many construction processes, and the links between them are close. Construction and preparation of carbon materials need to ensure a certain humidity, but also consume a large amount of compressed air and electricity. Therefore, the preparation work of material transportation, compressed air and electricity supply should be done well before construction.

Construction of Aluminum Electrolytic Cell

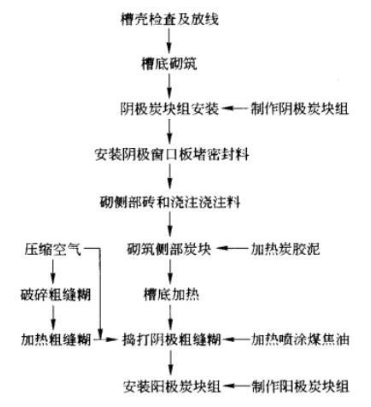

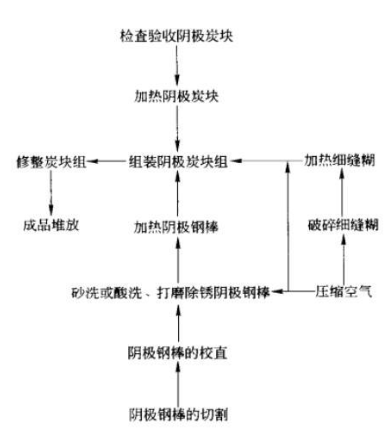

The construction of electrolyzer should start from one end of the workshop and organize the flow-line operation according to the construction process of each electrolyzer. Before lining the electrolyzer, the production of cathode carbon block group should be carried out in advance. The construction of electrolyzer and the production of cathode carbon block are carried out according to the following procedures, as shown in Fig. 1 - 3.

Before the construction of the electrolyzer, the cathode carbon blocks and coarse seam paste are transported by car from the carbon material warehouse to the assembly yard of the electrolyzer overhaul workshop, then unloaded by forklift truck to the assembly platform and heated in the kneading pot. At the same time, after rust removal, the heated cathode steel rod is hoisted to the assembly platform by a bridge crane. The qualified cathode carbon block group is repaired and inspected. It is transported to the electrolysis cell of the electrolysis workshop by automobile. It is installed by bridge crane and hoisting frame. Clay refractory bricks, heat insulation products and side carbon block are transported to the open space of the electrolysis workshop by automobile, and then stacked on the operating platform near each electrolysis cell by bridge crane. The heated rough seam paste is put into the paste box and pulled to the electrolysis workshop by car for reserve.

Before tamping, the vertical seam between the bottom carbon block group and the seam between the carbon block group and the side carbon block can be put into the seam by 4-5kW tubular or chip heater to heat it to the required temperature. If the local temperature is not enough after heating, the light oil heater can be used for local heating.

After the anode carbon block group is manufactured in the anode assembly workshop, it is transported to the electrolysis workshop by an anode tray truck and installed by a multi-energy bridge crane. Other auxiliary materials and powder can be transported by trolley.

Scan